Electrostatics is the science using the many characteristics of electrostatic forces. The fundamental principle is based on Coulomb’s Law: attraction of opposite electrical charges and repulsion of like charges. The principle behind this physics was applied first in the early 1900’s in electrostatic precipitators to remove dust particles from smokestacks. Later it inspired the development of electrophoresis, powder paint sprayers, xerography, separation of metallic ore from tailings, and ink jet printers.Terronics looks for creative ways to safely and effectively charge liquid or powder particles electrostatically so that they are attracted to intended products and provide a high quality coating.

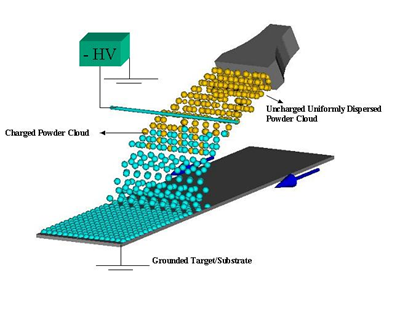

The electrostatic coating process is basically simple. The product is electrically grounded. The coating system creates charged powder or droplets, and disperses these over and towards the product by a variety of methods. The charged particles are attracted to the electrically grounded product and deposit on it.

Since all the particles are charged alike and they repel each other. During flight to the product and while “landing”, particles avoid each other and seek areas on the products surface that are best grounded (i.e., uncoated areas). This is the idea behind one of the many elegant aspects of electrostatic coating processes: deposition is uniform because the least coated areas get coated by the “newest” particles.

Through fine atomizing of liquid droplets, complete deagglomerating and diffusion of powders, eliminating or shielding unintended targets, design and creation of an optimal electric field, optimizing equipment geometry and orientation, choice of materials, etc. Terronics has succeeded in developing electrostatic deposition technologies which can be used in various processes.

Characteristics of well-designed electrostatic processes include low energy expenditure, absence of pollution or other undesirable effluents, and very high material utilization efficiencies. Its applications reduce waste and improve manufacturing efficiency and product quality. There are no adverse secondary effects from application of electrostatics. It is as efficient and basic to nature as the electron to proton attraction and as powerful as a bolt of lightning.